Pallet changers

Safe pallet changing in every branch of industry

Baust offers a wide choice of high performance machines in the field of pallet changers. No matter how varied the differing fields of application are, the Baust pallet changers are simple to operate, treat the goods gently and offer the highest safety standards. Whatever the focus, whether it is the adherence to strict hygiene regulations in the pharmaceutical or food industry, or the trouble-free operation in warehouse and logistics management, the Baust pallet changers are used in a wide variety of industries. Choose your Pallet changer and get in contact.

Repalletize processes with pallet changer

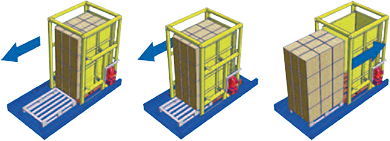

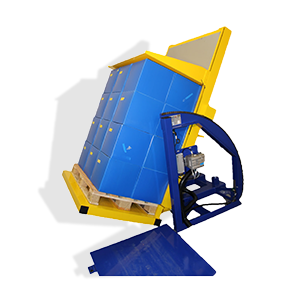

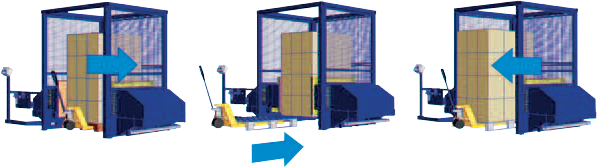

Pallet changers with the clamping method

Palletize robust goods quickly and cheaply

- Side clamping of the goods

- Simplest and cheapest option for particularly robust goods

- pallet inverting: Ideal for palletizing cardboard boxes and boxes

- Lowering and exchanging the pallet using a hand pallet truck or a lifting roller conveyor

- Performance: up to 50 changes per hour

Pallet changer

PW 500

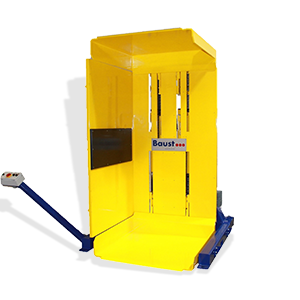

Pallet changer

PW 500 Inline

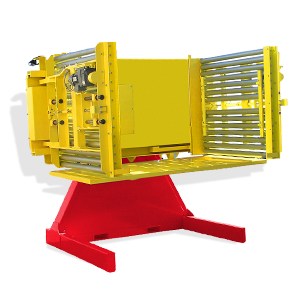

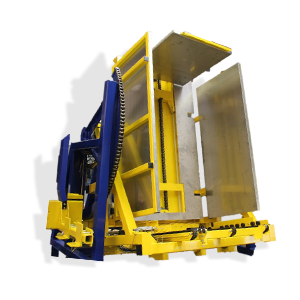

Pallet changers with the inverting and tilting method

Suitable for many pallet sizes

- Rotate or tilt the goods by 90 to 180°

- Ideal for palletizing sacks and big bags

- Overhang of the goods is not a problem

- Reliable even with poor pallet quality and different pallet dimensions

- Performance: up to 55 changes per hour

Pallet inverter

PW 600

Pallet inverter

PW 600 Inline

Pallet inverter

PW 700

Pallet changer

PW 800 E

Pallet changer

PW 800 C

Pallet changer

PW 800

Pallet changer

PW 800 Inline

Pallet changer

PW 900 Inline

Pallet changer

PW 1000

Pallet changer

PW 2000

Pallet changer

PW 3000

Pallet changer

PW 4000

Pallet changer

PW 5000

Pallet changer

PW 6000

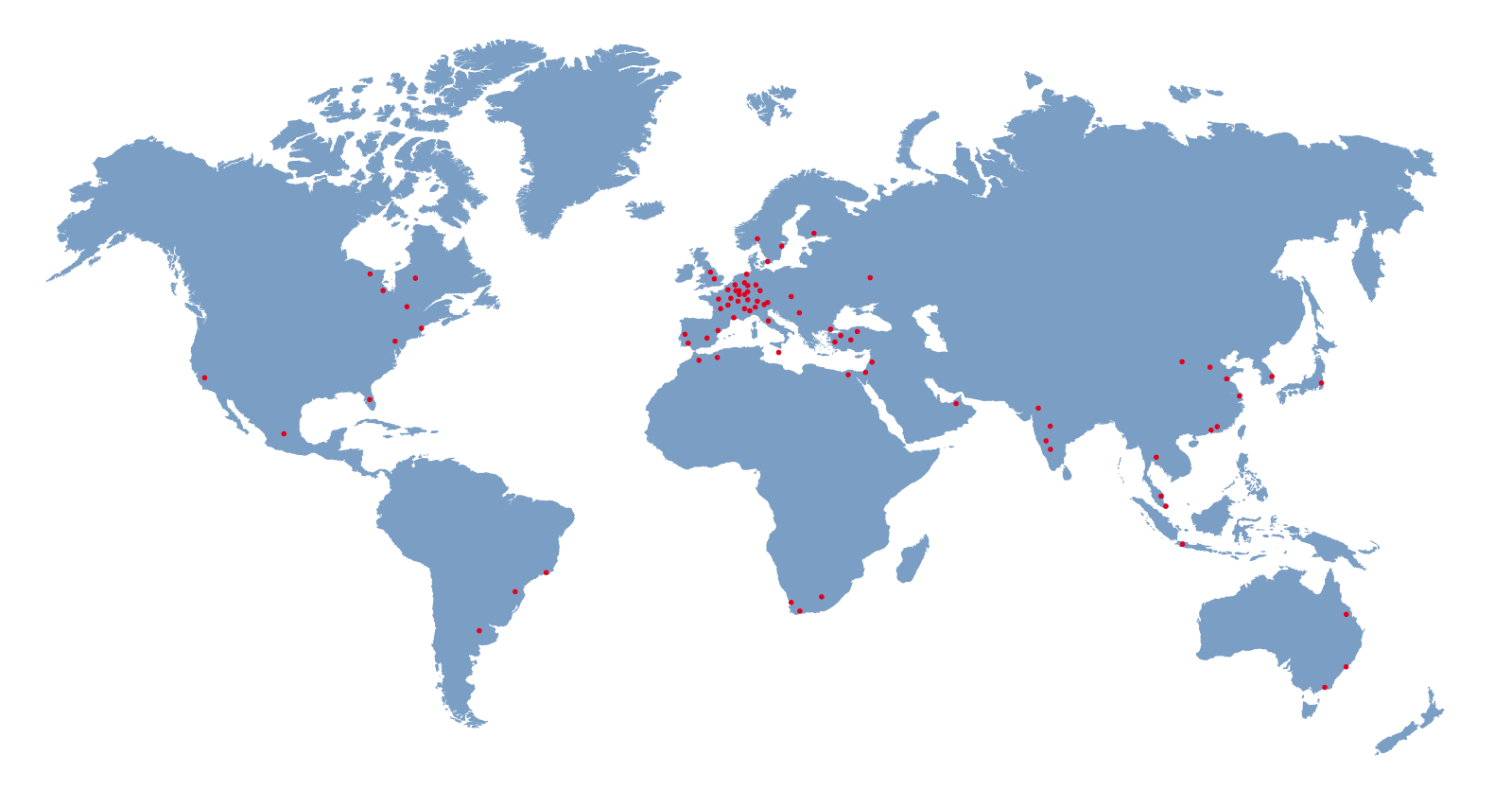

GLOBAL COMPANIES

who trust in Baust pallet changers

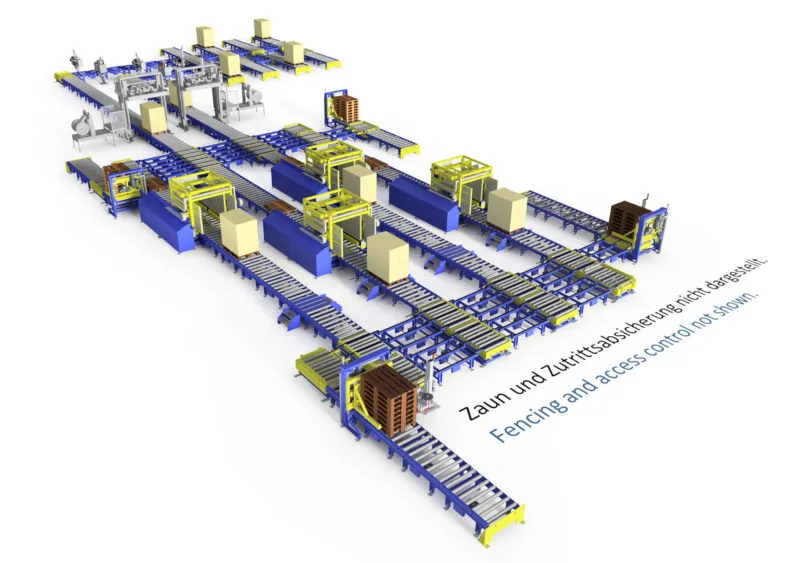

Powerful pallet changers for every industry

Pallet changers are used to repalletize sensitive goods and work more efficiently. In particular, the devices are used in the pharmaceutical and food industries, as they are compatible with the high hygiene regulations of these sectors. Pallet changers are characterized by their particularly gentle handling of goods and thus by compliance with a high level of safety. Pallet changers are also used to stack goods and exchange products. But even if a shipping pallet becomes necessary for transport, a pallet changer makes the changeover particularly efficient and cost-effective. In warehouse logistics, it is often necessary to change the location of products, for example, by correcting the orientation or changing the sequence. Pallet turners avoid burdensome and time-consuming manual work without losing the gentle handling of sensitive goods.

Common methods for pallet changers

Pallet changers are used in many different areas and offer new possibilities for the automation of logistics and transport processes in all industries. Typically, a pallet changer uses either the clamp method, the push-over method, or the turn-and-tilt method. Pallet changers that work with the clamping method are particularly well suited for working quickly and inexpensively. However, these devices are more suitable for robust goods than for sensitive goods. The products are clamped laterally, and up to 50 changes per hour are possible with our powerful devices. The pallet is lowered and exchanged, for example, by means of a lifting roller conveyor. Thus, pallet changers using the clamping method are the best way to automate the repalletizing of robust goods.

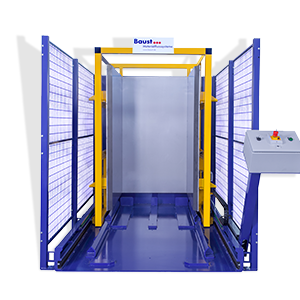

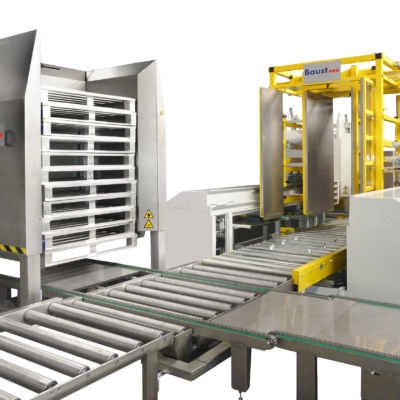

Overshifting method for pallet changers

In contrast to the clamping method, this method is exactly the right one if you are repalletizing sensitive products, such as in food transport or for the pharmaceutical industry. In this process, the products are pushed onto a lower plate, thus ensuring maximum safety for sensitive goods. In addition, the over-palletizing method can be used when the load is patchy or incomplete, whereas here the clamping method is not a good solution due to lack of stability. With a performance level of up to 60 changes per hour, you will not lose any time even if the products in question are handled very gently, and you can work just as efficiently as with more robust goods. Just as for the clamping process, different devices are available from us for pallet changers with overshifting process. We will be pleased to advise you individually on their special application possibilities and advantages.

Pallet changers – flexible options for automation

The third standard method for pallet changers is the turning and tilting method. The turning device is ideal for unusual or irregular formats, because even with different pallet dimensions or overhanging goods, there is neither a delay in performance nor reduced safety of the goods. The methodology is also ideal for bagged goods or big bags, as well as for poor pallet quality. The goods are tilted by 90° to 180°, which also allows a high output of up to 55 changes per hour. Please contact us for an individual consultation, in which we will determine your needs for pallet turners and inform you about the suitable products. Of course, we can also offer you hybrid solutions or complete systems if you want to work with a variety of products and reduce your expenses when purchasing the equipment.