Pallet changers using the pushing method

The pushing method does not involve inverting, tilting or clamping. Instead, the goods are gently pushed from the source to the target pallet. This makes the pushing process particularly gentle and ideally suited for the palletizing of sensitive goods.

Pallet changers using the pushing method are available in two basic versions:

As a free-standing stand-alone element or as part of a material flow system.

The pushing method offers a wide range of applications

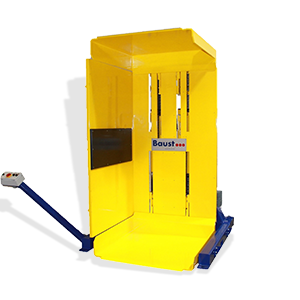

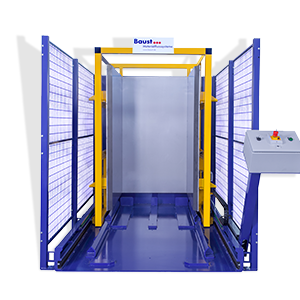

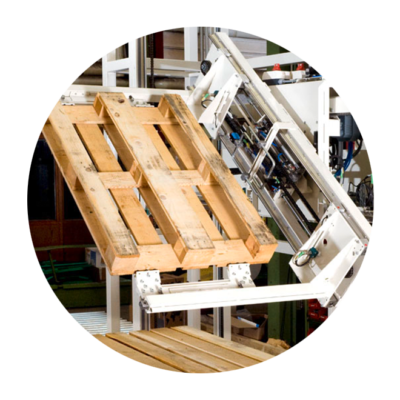

Freestanding pallet changer using the pushing method

Pallet changers using pushing method offer various options. They can be loaded from the front as well as from the rear. This makes them suitable for hygienic separation in the pharmaceutical or food industry. The pallet changers can easily be integrated into existing material flow systems. In this way, the most powerful exchangers make up to 60 changes per hour

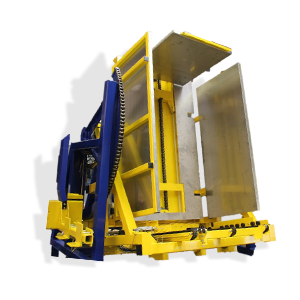

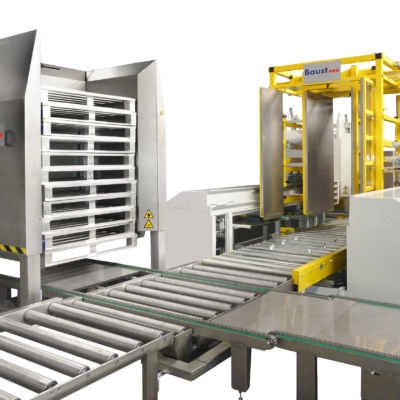

Pallet changer for integration into a conveyor system

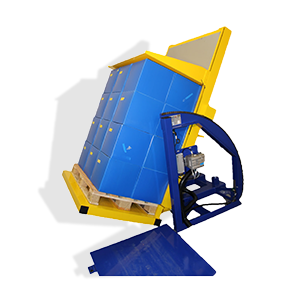

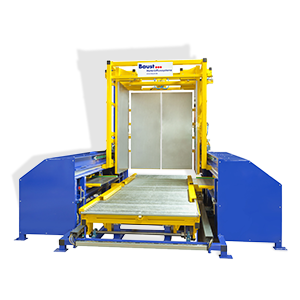

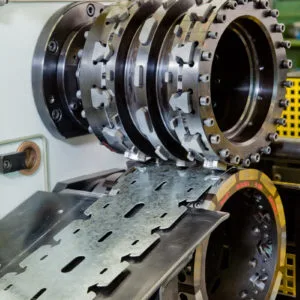

Common to all these machines is the method of pallet changing. The source pallet is slightly higher than the target pallet. Secured from 3 sides a frame pushes it onto the empty target pallet. When working with a stand-alone exchanger the repalletized load can now be removed. In a material flow system, however, the pallet is transported onwards by means of a conveyor.

Pushing method used by Pallet changers

Do you have particularly sensitive goods or pallets with incomplete loads? No problem! The Baust pallet changer in the pushing method reliably changes the pallets even with sensitive goods. With this method, the pallet changer does not clamp, turn or tilt. Instead, the goods are gently pushed from the source to the target pallet.

The side walls of the pallet changer cover the goods very carefully in order to prevent them from falling over or falling down. The source palette is slightly higher than the target palette placed in front of it.

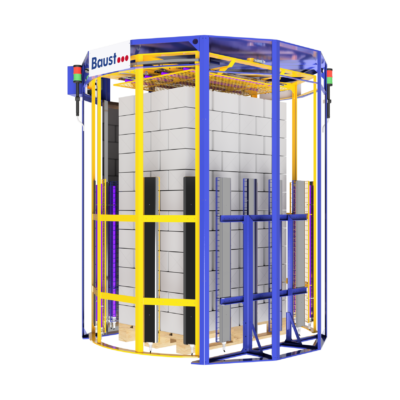

Then the pallet changer carefully pushes the entire stack onto the target pallet. Then it can easily be picked up by a forklift or a pallet truck. The most powerful pallet changer from Baust use this technology to achieve up to 60 changes per hour. The pallet changer in the pushing method is suitable both as a free-standing stand-alone element and as part of a conveyor system. The devices can be supplied with pallets on one or both sides and are therefore ideal for use in pharmaceuticals, food and logistics in high-performance logistics systems, hygiene lock areas or niche locations.

Free initial consultation & technical planning

- Kostenfreie Planung der definierten Spezifikationen

- Free planning of the defined specifications

- Fast, clean and binding development

- Non-binding offer and detailed documentation

- Technical expertise right from the start

- Consulting, planning, production, assembly and maintenance from a single source without subcontractors

Products using the pushing method

Pallet changer

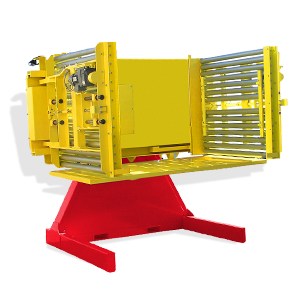

PW 500

Pallet changer

PW 500 Inline

Pallet inverter

PW 600

Pallet inverter

PW 600 Inline

Pallet inverter

PW 700

Pallet changer

PW 800 E

Pallet changer

PW 800 C

Pallet changer

PW 800

Pallet changer

PW 800 Inline

Pallet changer

PW 900 Inline

Pallet changer

PW 1000

Pallet changer

PW 2000

Pallet changer

PW 3000

Pallet changer

PW 4000

Pallet changer

PW 5000

Pallet changer

PW 6000

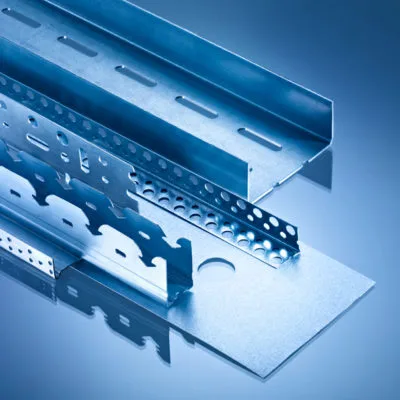

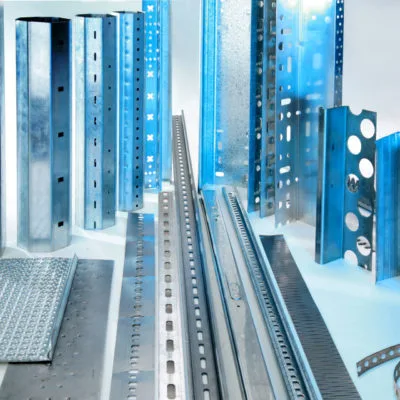

Construction Metal Industry

Pallet handling

Pallet transport

Drum handling & transport

Mesh boxes

Long goods transport

Container transport

Digital printing

Electro Industry

Shelf and storage technology

Roller blinds

Data protection - privacy policy

For particularly sensitive or incompletely packed goods, we recommend a pallet changer using the pushing method. Here the palletizer encloses the goods from several sides with gentle pressure from large side walls. The pallet changer then carefully pushes the entire goods onto the slightly lower target pallet.

In this way, you can also reliably palletize cellulose rolls, fruit boxes or pallets full of different goods. Our most powerful machines in the pushover process can handle up to 60 changes per hour.

Loading from two sides

The Baust pallet changer in the pushing method is available in several versions: It can be easily integrated into existing conveyor systems, but it can also stand alone. Some devices can be loaded from both the front and the back. This means that these re-palletizers can be used as a hygiene lock unit in the pushing process, for example in the food or pharmaceutical industry. Both the stand-alone elements and the palletizers as part of a material flow system are suitable for very sensitive goods. They are also designed to save space. With our flexible and easy-to-use pallet changers, we can surely fulfill your individual wishes!

Our models for your application

We have developed the PW 1000 for large and stable units. It convinces with its space-saving plug & play design and simple operation. In the PW 2000, two flexible side walls and the rear wall enclose the goods on three sides. Additional sliding plates convey highly sensitive goods to the target pallet with particular care. The PW 3000 with its clever two-way solution is particularly in demand for clean room lock units. It can be loaded and unloaded from both the front and the back. He systematically differentiates between internal and external pallets so that no third-party pallets get into the clean room. In this way, the PW 3000 fulfills the highest hygienic requirements when pushing over.

Pallet changers using the pushing method

The models PW 4000 and PW 5000 are the Inline variants of PW 2000 and PW 3000 for automatic conveyor systems. The PW 5000 also serves as a fully automatic lock unit with a clear separation between the clean room and the outside. We have designed the PW 6000 for particularly high quantities, which can push up to 60 changes per hour. Slip sheets protect sensitive goods from rough pallets. These are automatically centered so that the sensitive goods come to be centered on the pallet. So you can trust the quality of the Baust pallet changer even with very sensitive goods and with the most different requirements!

Master the pushing method now!

Request a non-binding inquiry