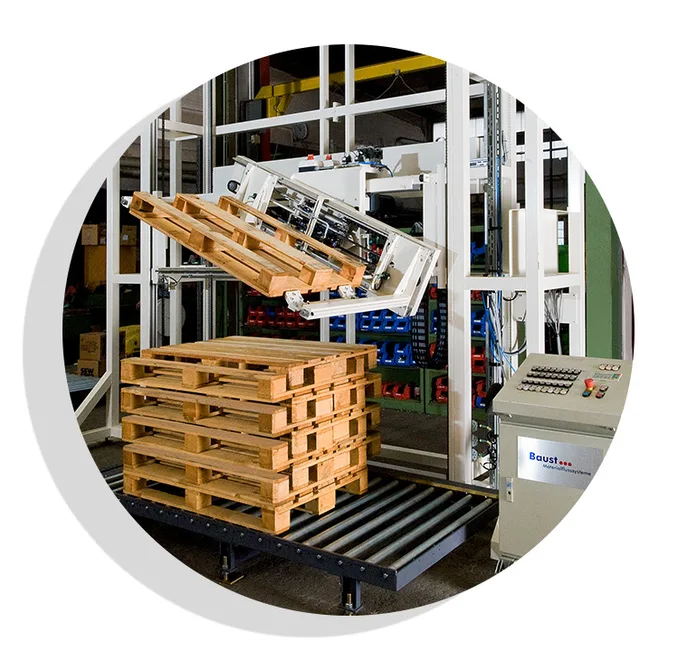

Pallet turner

Effective pallet management with a powerful palletizer

When stacking pallets, space-saving solutions are required. If they are stacked in a conventional manner, the company wastes plenty of storage and cargo space. If the pallets are stacked nested, however, more pallets can be stored and transported. The company Baust has developed a handling system for the optimization in pallet management, which improves these processes significantly: the pallet turner.

- dispenses and collects pallets of various sizes

- can even grip overturned pallets

- simultaneously turns and centres pallets

- saves shipping space and inconvenient re-stacking as pallets can be processed in stacks

- for up to 25 pallets

- optical pallet size recognition

- leakproof due to pneumatic or electric systems

- robust, durable and long-lasting

Specifications

- Performance: 20 – 40 cycles / h

- dimensions (L x W x H in mm): 1960 x 4120 x 4260

- clamping/turning/lifting: pneumatically and electrically driven

- loading and unloading: conveyor line

- control mode: automatic

- Power supply: 4kVA 16 A 230/400 V R1/2″, 6 bar

Pallet data

- dimensions (W x L in mm): 800 – 1000 x 1200

- max. stacking height: 3600 mm (25 Euro pallet)

- max. stack weight: 625 kg (25 Euro pallet)

- material: wood, plastic, aluminum

Options

- other pallet types

Pallet Turner: Pallet management in the food industry

For a mid-sized company in the food industry, Baust-Materialflusssysteme planned and designed a pallet turner with attached conveyor technology. The process is as follows: Integrated light barriers in the palletizer recognize the pallet size. Then two pneumatically movable gripper arms take the pallet from the side. The pallet turner centers it and, if necessary, rotates it by 180°. The pallet is now fully prepared and can be handed over in a central orientation to the conveyor system. Further processing steps, for example the loading of the pallet, are now possible.

Request a non-binding offer now

Pallet turners for more efficiency in the warehouse

In order for a warehouse to be used optimally, a well thought-out use of the space is very important. A so-called pallet turning station makes it possible to manage a warehouse in a space-saving and also time-saving way. A pallet turner is a machine that can stack pallets of different sizes on top of each other in a space-saving way and in no time at all. In order to save as much space as possible when storing or transporting pallets, pallets can be nested and stacked on top of each other. To do this, two pallets are placed on top of each other with their undersides facing each other. These then fit together like two pieces of a jigsaw puzzle and thus take up far less space than other stacking options. The interlocked pallets can now be easily stacked on top of other interlocked pallets, creating a tall, space-saving pallet tower. The pallet turning station is used whenever a pallet is to be turned to a desired side and placed on another pallet. The machine takes over this time-consuming work step and thus enables a fast sorting of pallets.

Pallet flipper high quality machine for optimal stacking of pallets

In addition to turning pallets, the pallet flipper is also able to center pallets optimally so that all pallets can be stacked perfectly and safely on top of each other. The pallet turning station is suitable for up to 25 pallets per tower and can grip pallets from both sides. If you want to stack and store your pallets effectively and neatly, our pallet turning station is perfect for you. We at Baust offer you a high-quality and therefore also very durable machine, which simplifies the processes in your warehouse. Feel free to contact us and let us manufacture a pallet flipper perfectly adapted to your company. We respond to the individual requirements of our customers and find an optimal, profitable solution for everyone. As specialists in palletizing, we can give you valuable tips to facilitate all the work that arises in the field.

Buying a pallet turner and improving and accelerating warehouse processes in the long term

With the help of a pallet turner, you can work in a space-saving and uncomplicated way. It facilitates the work of the employees of your warehouse and allows to devote more time to other, more important tasks that arise in a warehouse. Since pallets are part of every warehouse, it is of great importance to store them in an optimal way. This way you can prevent the existing pallets from taking up too much space, which is actually intended for your goods. If you invest in a pallet turning station, you can use your warehouse in the best possible way, simplify work steps and increase efficiency. If you are now interested, we will be happy to advise you in detail.

Our competent team can explain you in detail the function, construction and performance of our machines. Whether by mail or by phone, feel free to contact us!

Buy a high-performance, storage process-simplifying pallet turning station from Baust

When it comes to pallet turning stations, we are your competent advisor! The many years of experience and the wide-ranging expertise of our team enable us to find optimal solutions for every warehouse. No matter what industry you come from, we will make a pallet turner perfectly tailored to your needs and improve the processes in your warehouse. If you are interested in optimizing the processes in your warehouse, a pallet flipper is exactly what you need! Our robust pallet flipper is made of a combination of wood, plastic and aluminum

This makes it very durable and hard-wearing. It can therefore withstand the daily stresses and strains in a warehouse and makes power-intensive work steps much easier. If you use a pallet flipper in your warehouse, you can optimize processes and thus work more profitably and intelligently. Make everyday life in your company easier for yourself and your employees and get yourself a high-quality pallet turner.

With the help of a pallet turner, you can easily stow pallets in a space-saving way

When it comes to palletizing, we will find perfect solutions tailored to your needs. The use of innovative technologies and advanced machines in the warehouse is very worthwhile in the long run. Not only do you relieve your employees, you also enable a greater amount of work to be done in the same amount of time. This in turn increases the success and also profit of your company. It is therefore an investment that will bring you forward. With a first-class pallet flipper, you are guaranteed not to go wrong. The device is easy to use and makes stacking pallets a breeze. A pallet flipper from Baust meets all your needs and can be used in a wide variety of warehouses. Whether it’s a small or large company, a successful logistics department shouldn’t be without a pallet turner. With 20-40 cycles per hour and automatic control, our machine is very advanced. Moreover, since our pallet flipper is capable of handling different types and sizes of pallets, it is very versatile.